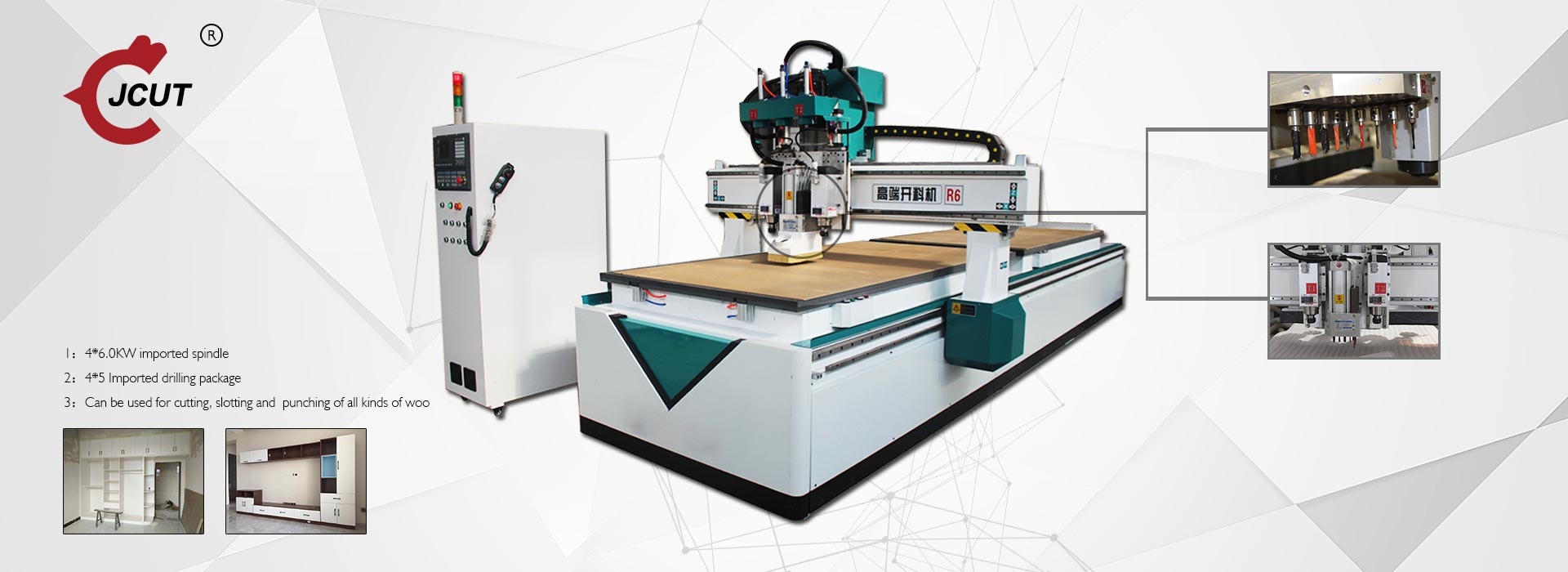

Feature:

Machine Description

1. The price is relatively low: suitable for small and medium-sized furniture factories. Even the high-end 12-30 thousand four-process CNC blanking machine is relatively low in price compared to the model with drill bag. It is a good choice for furniture factories with relatively large financial pressure.

2. Door panel cabinet dual-use: From a structural point of view, the four processes belong to the simple tool changer model, which uses four spindles to realize the tool change function by pneumatic switching. The cabinet body can meet the function of cutting and punching, and can also be used for simple door processing.

3. Simple operation: Compared with the row drilling and cutting center, the operation of the four-process cutting machine is relatively simple and easy to learn, and once one main shaft fails, the equipment can also complete the function of cutting and drilling through three main shafts.

Machine Application

1. The process of automatic order removal, optimization, design, cutting, drilling, milling, troughing, automatic cutting and other processes of the cabinet are completed at one time. Four-process blanking machine, four-step blanking machine advantages, CNC blanking machine.

2. Wood door and furniture decoration industry: solid wood and composite door, cabinet door, large area plate plane carving, solid wood carving and milling, panel furniture carving, antique mahogany furniture carving, solid wood art mural carving and other industries.

3. Wooden handicraft processing: clock frames, craft photo frames, thin aluminum plate handicraft carving and carving, electrical countertops, sports equipment. Four-process blanking machine, four-step blanking machine advantages, CNC blanking machine.

4. Electronic product industry: engraving and milling of circuit boards, insulating materials, LED display screens, household appliances (color TVs, washing machines, refrigerators) shells or models.

5. Musical instrument production industry: Carving the three-dimensional curved surface and shape cutting of musical instruments, such as engraving and milling of large and violin panels and heads.

Parameters:

Configuration

|

Longteng third-generation four-process R4-speed cutting equipment |

|

| Technical Parameters | |

| Working Area(S*Y*Z) | 1220*2440*200mm(Support length 2800 customization) |

| Spindle speed | 0-18000/MIN |

| Spindle Power | GDZ Air Cooling Spindle 6KW*4 |

| Tool Magazine | 6KW*4 |

| Motor | Leadshine Big Power 1500w servo motor |

| Control System | Import Taiwan LNC MW2200 control system |

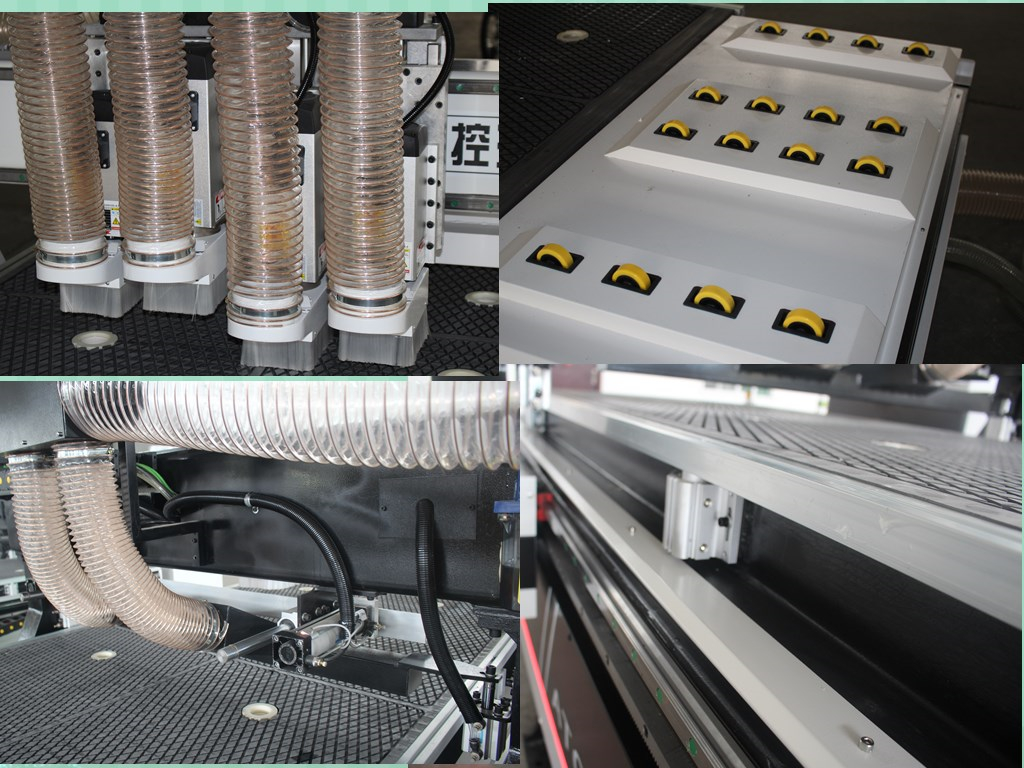

| Vacuum Machine Table | Patented design 50MM adsorption caliber, good sealing of PVC pipeconnection, no running board |

| Adsorption pump | Water circulation 7.5KW,( Strong adsorption force, high stability when processing products) |

| Dust Collector | 5.5KW Dust Collector with two bags |

| Driver | Matching servo motor driver |

| Inverter | Four-in-one frequency conversion, pre-start |

| Tool changing speed | Zero second switch |

| The transmission track | Genuine original 25 square gauge |

| Slider | Genuine original 25 slinder |

| Lead screw | TBI original 2510 Lead screw |

| cable | Highly flexible shielded towline cable |

| Limit | Dedicated to the forward and reverse direction of the wood cutting router |

| rack | Original HICK |

| Electrical components | Genuine original Chint |

| Reducer | Genuine original Modoli |

| cylinder | Huadeli (good quality and strong durability) |

| Empty speed | 100000MM/MIN |

| Maximum working speed | 35000MM/MIN |

| Overall appearance | The third generation Longteng patent structure (independent control cabinet) |

| Bed structure | Heavy-duty aging welding bed (five-sided milling drilling accuracy 0.02mm) |

| Gantry |

Machining process of synchronous beam bed with thick-walled square tube and steel strip for beam

Column integral casting structure does not deform for a long time |

| Electric control operation cabinet |

Longteng patented cabinet series, fully sealed intelligent operation cabinet |

|

Tool

setting method |

Automatic tool setting |

| Positioning | Positioning cylinder |

| Automatic unloading | Automatic unloading |

| Dust removal method | Spindle automatic partition type integrated dust removal and secondary dust removal with pusher |

| Voltage | AC380V |

| Net Weight | 2600KG |

| Gross weight | 2700kg |

| Wooden Box | We Provide Standard Export Wooden Box |

| Warranty |

1 Year |

| Optional parts | Software in CD, Controlling Card (PCI card), Engraving And Cutting Tools, Allen Keys, Wrenches for Collet locknut, Data Wire, Power Line, Brush, Spanner and Clamp. (These tools all free to you) |

Jinan jcut cnc Equipment Co. Ltd.

Jinan jcut cnc Equipment Co. Ltd. Chinese

Chinese English

English